Z-TEC Feeding Technology: Your benefit

3-D Design

The base of the technical performance

• Benefit repeatability

Clear reduction of throughput time and cost optimization

Cutting manufacturing

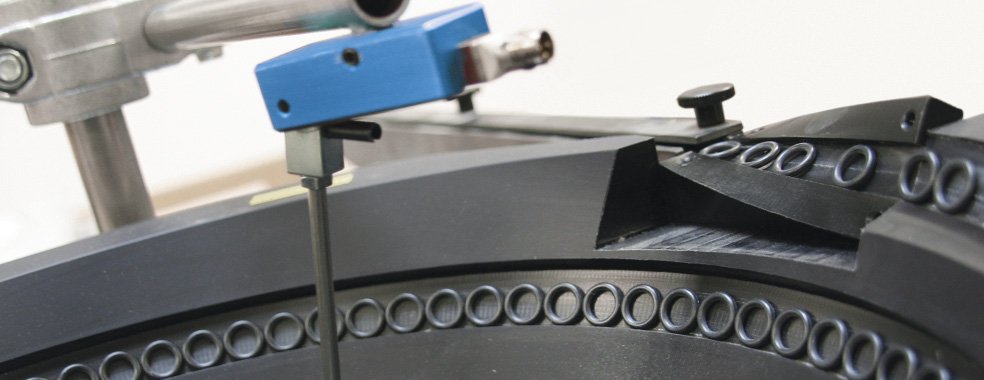

All bowl feeders are made of polyamide and are manufactured by a milling machine with 5 axis (simultaneously)

• Benefit precision

Highest precision and repeatability of all components

Variable outer diameter

Outer diameter of bowl feeders may vary between 100mm and 600mm

• Benefit flexibility

Individual adaptation as required

Documentation

Customers from Z-TEC are getting a extensively tested and well documented (e.g. via video) feeding system.

• Benefit reliability

Proof of output and availability

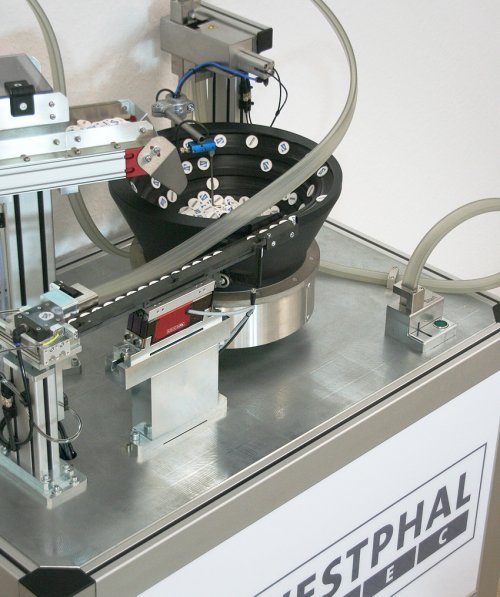

Feeding systems: Possibilities

Feeding systems

Base for all feeding systems:

- Vibration bowl feeder – Made from Polyamid by milling with 5-axis machines (Not solded)

On customer’s requirement added with:

- Linear feeding system

- Right positioning of single parts (if necessary by camera)

- Parts stores

- Frame (aluminium)

- Noise protection

- Wiring and tubing

- Program and control

Vibration bowl and linear feeding systems

Characteristics

- Flexible inclination (MILLED)

if required

- Flexible positioning of part

by chicanes

- Adaptable friction

by diverse surface treatment

- Precision and variable feeding

e.g. by tubes

- Length up to 1000mm feeding

by use or more linear feeding systems

- Service friendly

simple to clean